The overall environment to be experienced in the global budding vase import market in 2026 is a paradigm change to one based upon mere price-arbitrage and, in lieu, a sophisticated grid of technical accuracy, logistical robustness, and high-level compliance with ESG. To both new startups and established retailers, the key to success in this saturated marketplace is complete, integrated business collaborations with high-tech services and equates to success with Mosteb. This plant is a balancing point, it has been able to combine the production efficiencies of mass production with the sensitivity of the artisanal quality. The report gives a detailed review of the manufacturing hubs, technical standards and digital solutions that the industry is currently characterized by.

1. Mapping Global Manufacturing Hubs

What analysts term the Great Realignment is being experienced within the geography of production of glass. The new wave has changed the criteria of selecting the partners such that the energy stability, technological integration, and geopolitical de-risking have become the priority over the old labour cost benefits.

1.1. China’s Scalability and the Mosteb Advantage

China has continued to dominate in this emerging vase importation industry with an unrivalled industrial infrastructure and an enormously specialized labor force. The Mosteb is representative of the contemporary Chinese manufacturing method with the use of state-of-the-art automated IS (Individual Section) machine that can manufacture high precision borosilicate and soda-lime vessel on a large scale. This infrastructure enables the importers to enjoy considerable economies of scale and still preserve the fragile aesthetics of developing vases. Additionally, the high local capabilities of mold-making will enable Mosteb to shorten the concept-to-shelf durations by a large margin, enabling the brands to respond to micro-trends in real-time.

1.2. Mexico’s Nearshoring Logistics and the USMCA

| Region | Primary Strength | Average MOQ | Lead Time | Sustainability Index |

|---|---|---|---|---|

| China (Mosteb) | Technical Precision / Scale | 5,000+ | 45-60 Days | High (Electric Transition) |

| Poland | Artisanal Clarity / Heritage | 500+ | 90-120 Days | Medium (Gas Dependent) |

| Mexico | Logistical Proximity / USMCA | 2,000+ | 20-30 Days | Medium (Nearshoring) |

2. Technical Quality and Craftsmanship Standards

Quality in any thriving budding vase business lies in the very accurate point of intersection of physics, material science and beauty.

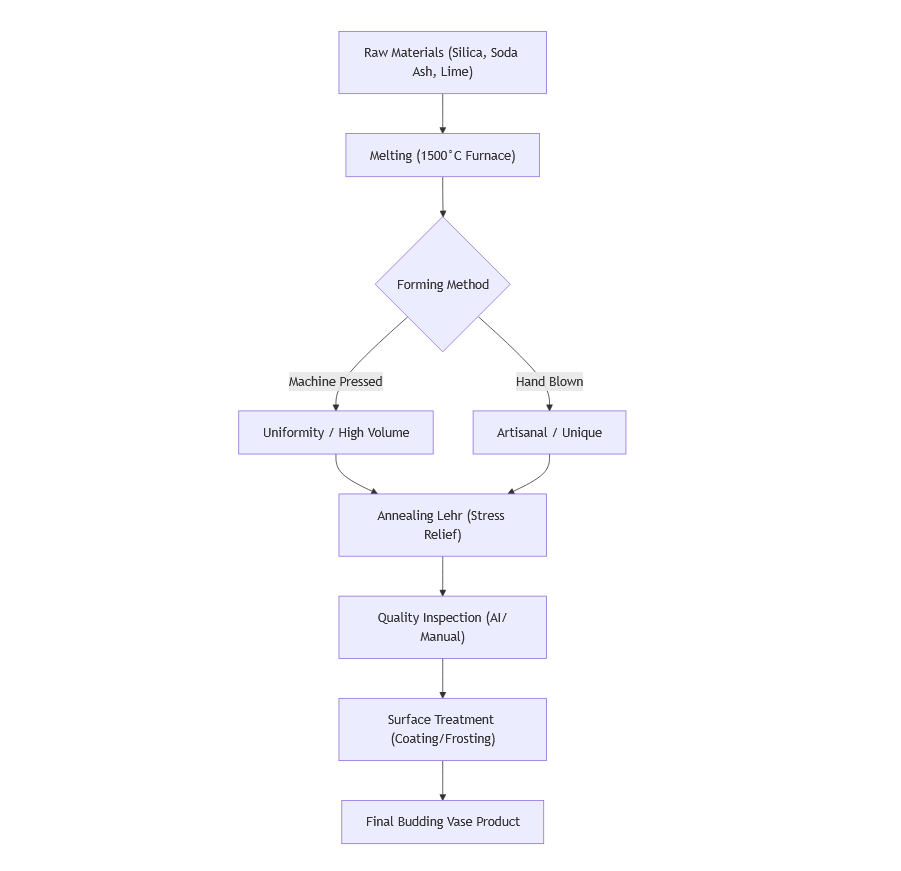

2.1. Annealing Integrity and Thermal Resistance

The annealing lehr is the most crucial part of the production in the Mosteb facility. It is a kiln which is temperature regulated and the glass cools at a strictly regulated rate in order to relieve the internal stresses. We are using polarized light stress viewers to check on each batch on birefringence. An excellent Mosteb vase will show a consistent distribution of colors when the polarized light is used, which is the indication of a stable molecular arrangement, which is very impervious to thermal shock and spontaneous fragmentation during transportation and usage.

2.2. Optical Clarity and Refractive Indices

The purity of the silica sand is what determines the brilliance and the whiteness of the glass. When dealing with high-end imports the iron oxide content is more than required to be kept at a very low level of below 0.01% to prevent the typical shade of greenish color which is characteristic of lower grade substances. Mosteb applies the superior quality of selenium and cobalt de-coloring to remove any residual impurities to give a crystal clear finish. In technical vetting, a measure of light dispersion of the material (specified as an Abbe number) is an effective measure of technical richness of a manufacturer.

2.3. Machine-Pressed vs. Hand-Blown Trade-offs

Machine-pressed vases provide the desired degree of uniformity necessary in standardized retail packaging and automatic filling, but can occasionally have small grocery mould seams. On the other hand, hand-blown works present individual variations, which are favoured by the slow-made movement. A high-tech import strategy usually combines the two: with precision-pressed glass, which is inexpensive in large volume retail clients, held back, and finished by hand to reserved for limited-edition boutique lines.

3. Supply Chain Resilience and Fulfillment Metrics

Because of the nature of glass, where it is fragile, the landed-intact cost instead of FOB price is the chief measure of commercial success.

3.1. MOQ Optimization and Lead Time Reliability

Mosteb normally demands greater quantities to compensate machine calibration, but the process of uniting the current production within the similar glass types can be referred to as campaign manufacturing that can be employed in reducing MOQs of smaller brands. Instead of focusing on averages, importers should focus on monitoring the Lead Time Variability. The most dependable partner such as Mosteb offers 95 percent confidence interval on the delivery dates and enables shorter inventory turns and less warehousing overheads.

3.2. Specialized Packaging Engineering

We highly suggest the application of “Drop-Test Certified” (ISTA-1A or 3A) packaging. This entails injection-molded assorted pulp inserts or high-density EPE foam. Mosteb conducts intensive field testing to recreate the conditions of the last-mile delivery setting. Investing in 200lb-test double-wall corrugated boxes, though it might raise first shipping expenses by about 5 percent, usually brings down the breakage rates down to below 1 percent of an industry average of 8 percent.

3.3. Risk Mitigation in Fragile Logistics

It is also necessary to protect against a specific maritime risk, which is the use of an All-Risk marine insurance covering concealed damage. Additionally, resilience strategy includes port-entry diversification (e.g. dividing shipments into Long Beach and Savannah) so that in the case of a localized labor conflict or extreme weather conditions is not able to cripple the entire supply chain.

4. Sustainability and Social Responsibility Audits

The new generation consumer is becoming increasingly concerned that a young vase import should reflect their environmental and ethical principles. There is no longer an option of transparency.

4.1. Decarbonizing the Glass Furnace

Mosteb is now spearheading the industry transformation into electric-melt technology. The facility emits Scope 1 carbon into the atmosphere at 40 percent less than the conventional gas-fired furnaces by directly heating the melted glass using molybdenum electrodes. The use of renewable energy credits (RECs) is a priority in factories to future-proof the brands in the anticipation of future carbon border taxes, including the EU CBAM (Carbon Border Adjustment Mechanism).

4.2. Ethical Labor and the Circular Economy

Third-party social audit (SMETA or BSCI, etc.) is required to cover fair payment, safety of the workers, and moral treatment. Environmentally, it is crucial to incorporate cullet (recycled glass refined). Cullet lowers the furnace temperatures needed, and saves on the overall energy use. The sophisticated refining systems of Mosteb permit to include 20-30% of recycle material without losing the aesthetic clarity and mechanical strength of the end product.

5. Advanced Vetting through Digital Innovation

The Industry 4.0 technologies also eradicate human error and subjectivity out of the import and quality control process quickly.

5.1. AI-Driven Quality Control and Blockchain Traceability

Mosteb applies camera systems that are of high speed, AI-powered equipment on the production line to scan micro-cracks, stones, and chokes that are usually not visible to the human eye. This guarantees a Six Sigma standard of quality. Moreover, blockchain is also introduced to offer complete transparency; each production batch will be given a special digital ID with which importers can present end-consumers with a birth certificate containing details on the origin of the individual raw materials and the precise carbon footprint of its vase.

5.2. Digital Twins in Glass Design and Prototyping

Mosteb uses simulations based on the Digital Twin before a single physical mold is cast to model the flow of molten glass in the mold. This predictive modeling can detect possible weak points, thin points or uneven cooling of a virtual environment. The sampling stage is accelerated by this technology and the number of R&D overhead involved in coming up with unique, proprietary vase shapes is also greatly minimized.

Conclusion: The Path Forward for Mosteb Partners

A complex blend between the old craftsmanship and new world digital technology is needed in the budding vase import business that is currently thriving. With the help of a progressive, technology-empowered factory, such as Mosteb, the importers are able to take advantage of AI-powered quality assurance, eco-friendliness, and logistical skills. This is a way of positioning the brands with a strong, high-end image in an international market that is rapidly becoming more technologically superior and environmentally responsible rather than low-cost manufacturing.