Un rapport d'une importante usine de flacons diffuseurs en verre révèle que le marché mondial des emballages de parfums, évalué à environ 3,52 milliards de dollars en 2024 et dont la valeur devrait atteindre 5,83 milliards de dollars d'ici 2035, connaît une profonde transformation. Cette transformation est impulsée par l'évolution des préférences des consommateurs, les progrès technologiques et une demande croissante de durabilité. Pour des marques comme Mosteb, s'orienter dans ce contexte complexe exige une approche stratégique en matière de conception, d'innovation des matériaux, de partenariats de fabrication et d'optimisation de la chaîne d'approvisionnement. Ce rapport explore ces domaines essentiels et offre un panorama complet de la situation actuelle et des perspectives d'avenir, en mettant l'accent sur la capacité d'une usine leader de flacons diffuseurs en verre à répondre aux exigences élevées du secteur des parfums de luxe.

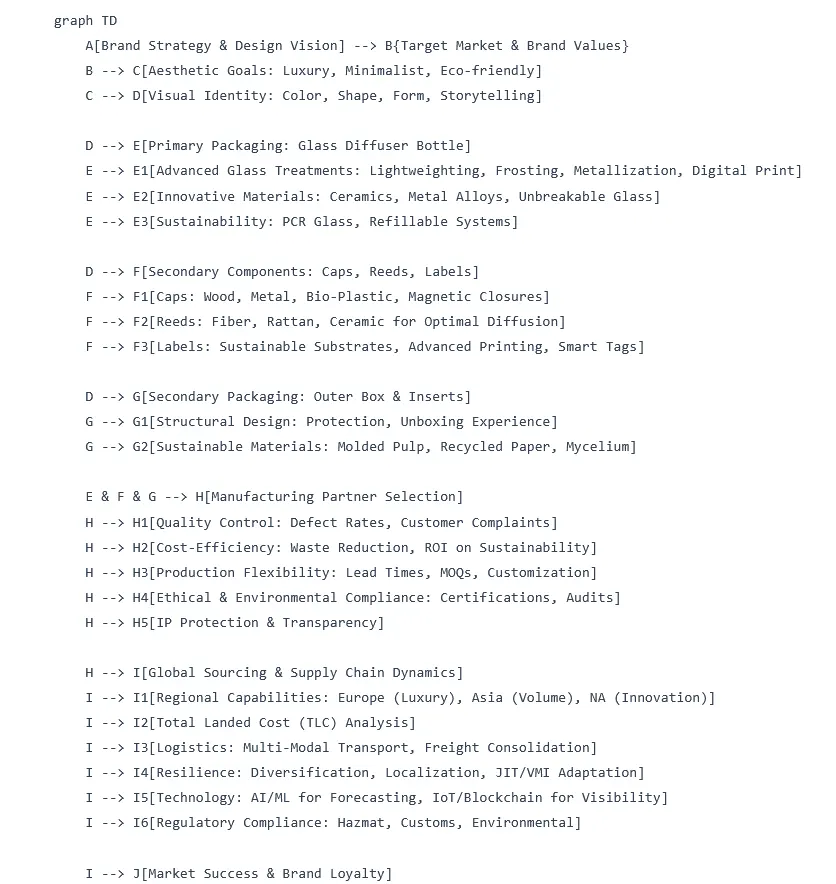

1. Créer l'identité visuelle de votre marque

L'identité visuelle véhiculée par le packaging d'un parfum est bien plus qu'un simple contenant ; c'est un véritable « prologue tactile » qui communique les valeurs de la marque, crée un lien émotionnel et instaure un rituel précieux chez le consommateur. Chaque choix de design, jusqu'au moindre détail, doit refléter le ton de la marque, qu'il s'agisse d'une marque de luxe, minimaliste, éco-responsable ou grand public.

1.1. L'art de raconter des histoires par le design

L'emballage des parfums de luxe devient un outil narratif d'une puissance extraordinaire, transformant le simple acte d'achat en une expérience immersive. La sensation au toucher, la couleur choisie et le poids s'harmonisent parfaitement pour renforcer le lien émotionnel entre la marque et le client et élever le parfum au-delà de sa fonction première, renforçant ainsi la notoriété de la marque et fidélisant sa clientèle. Le souci du détail, comme la précision du gaufrage du logo, la subtilité de la texture du papier, la douceur du ruban de satin ou l'éclat de la feuille métallique, est primordial. Tous ces éléments témoignent du savoir-faire artisanal et de l'exclusivité de la marque, tandis qu'un contrôle qualité rigoureux garantit le respect des plus hauts standards d'excellence.

1.2. L’expérience sensorielle : le toucher, la vue et l’ouïe

L'emballage de luxe repose en grande partie sur le toucher, qui englobe des attributs tactiles tels que le papier doux au toucher, les doublures en soie ou en velours, le verre épais et froid, et les bouchons magnétiques bien conçus, offrant ainsi une expérience de déballage multisensorielle. Les revêtements doux au toucher procurent une sensation veloutée, flattant les sens et conférant une impression de luxe. De plus, le gaufrage (motifs en relief), le débossage (motifs en creux) et le marquage à chaud (accents métalliques) créent non seulement une profondeur et un raffinement visuels, mais rendent également la marque plus mémorable et offrent au consommateur une expérience tactile agréable. L'apparence et le toucher sont encore sublimés par des finitions spéciales telles que le vernis UV sélectif sur les logos, le film holographique ou le vernissage/dépolissage du verre des flacons. Même le « clic » de qualité d'un vaporisateur bien conçu et d'un bouchon magnétique contribue à cette impression. Ce sont donc ces petits détails réalisés avec précision qui constituent l'essence même de l'emballage de luxe.

En définitive, l'emballage est le principal facteur qui influence directement la valeur et la qualité perçues, justifiant ainsi les prix élevés. Les emballages de luxe sont perçus par les consommateurs comme un gage d'exclusivité et de prestige. Une étude révèle que 72 % des acheteurs sont influencés par le design de l'emballage et que 61 % sont plus susceptibles de renouveler un achat si celui-ci est présenté dans un emballage luxueux. Le lien émotionnel créé par la narration et le rituel du déballage est ce qui, au final, fidélise le client et encourage les achats répétés.

2. Conception d'emballages complète et innovation des matériaux : l'approche de l'usine de flacons diffuseurs en verre

L'expérience de marque à travers l'emballage est l'intégration de tous les composants de l'emballage, depuis le produit primaire jusqu'au produit final. flacon diffuseur en verre Des bouchons aux tiges, en passant par les étiquettes et les emballages secondaires, l'article aborde, outre l'uniformité de l'expérience de marque, les traitements de surface du verre, les matériaux écologiques et les techniques de production innovantes qui définissent la norme pour les emballages de parfums de nouvelle génération.

2.1. Emballage primaire : Le cœur du parfum

Le verre Flacons diffuseurs Les procédés de fabrication mettent l'accent sur le fait que le verre demeure le matériau de prédilection pour les flacons de parfums de luxe, grâce à sa beauté, sa durabilité, son excellente conservation du parfum et sa capacité à véhiculer une image de grande qualité. Le poids et l'épaisseur du flacon contribuent grandement à donner au produit une apparence plus luxueuse.

Traitements et innovations avancés pour le verre

- Allègement :Le verre borosilicate permet de réduire l'épaisseur des parois de la bouteille, diminuant ainsi son poids total et les émissions de carbone liées à son transport. La technique DobleAlto d'Estal crée l'illusion d'une bouteille plus haute et plus lourde sans augmenter le volume ni le poids du verre, préservant ainsi une impression de luxe tout en améliorant l'impact environnemental.

- Propriétés de barrière améliorées : Les revêtements colorés internes, comme ceux de Heinz-Glas, mettent en valeur l'esthétique du verre tout en lui conférant des propriétés de barrière. Le verre dépoli, obtenu par différents procédés, offre une protection UV essentielle, préservant ainsi les formulations parfumées sensibles à la lumière.

- Texturation de surface sophistiquée :La gravure à l'acide permet d'obtenir une surface lisse, translucide, mate, voire opaque et givrée, utilisée par des marques comme Chanel et Dior pour leurs créations complexes et pour son toucher soyeux, évoquant la peau de pêche. Le sablage offre une surface plus rugueuse, tandis que le givrage par pulvérisation est utilisé à des fins décoratives, pour la protection UV et pour une meilleure adhérence.

- Métallisation: Ce procédé consiste à déposer de très fines couches de métaux (or, argent, aluminium, etc.) sur le verre. Le métal améliore ainsi la résistance à l'usure, la conductivité, la réflexion et la résistance à la corrosion, tout en conférant au verre un aspect brillant et texturé. Cette méthode permet d'obtenir des métallisations translucides, des dégradés métalliques et des finitions texturées.

- Effets de gradient : Les effets de couleurs dégradées, qui représentent 18 à 22 % du marché des parfums haut de gamme, constituent une tendance qui peut être réalisée soit par des techniques avancées de revêtement de verre, soit par mélange de couleurs de poudres métalliques.

- Impression numérique polyvalente : L'impression numérique est un procédé qui permet d'imprimer directement sur verre des motifs de haute qualité, aux couleurs vives et éclatantes, des images photoréalistes et des motifs complexes, grâce à des encres polymérisables aux UV. Cette méthode est très flexible et particulièrement économique pour les petites séries et les personnalisations rapides.

- Techniques de décoration diverses :Les autres méthodes sont la sérigraphie (polyvalente et durable), la tampographie (surfaces courbes, détails précis), le marquage à chaud (feuille métallique de luxe) et la gravure sur verre/le marquage laser (motifs complexes et permanents). Le revêtement holographique est une couche plaquée stable et colorée.

Matériaux d'emballage primaire innovants autres que le verre

Si le verre domine, d'autres matériaux émergent pour l'emballage primaire, notamment pour les diffuseurs :

- Céramiques haute performance : Les diffuseurs en céramique offrent une esthétique haut de gamme, élégante et minimaliste, s'intégrant parfaitement à la décoration intérieure. Ils offrent une résistance supérieure à la chaleur, contribuant à une durée de vie plus longue du produit, et leur densité minimise le bruit de fonctionnement. Les surfaces en céramique sont également plus faciles à nettoyer et à entretenir.

- Alliages métalliques légers : Les métaux comme l'aluminium et le titane offrent une esthétique moderne et minimaliste, permettant des détails complexes et des formes de bouteilles non conventionnelles. Les bidons en alliage d'aluminium usinés CNC avec bouteilles rechargeables favorisent le développement durable en réduisant les déchets plastiques.

- Technologie du « verre incassable » : Verescence a mis au point une technologie de pulvérisation qui enveloppe le verre comme une seconde peau, le rendant résistant à la casse tout en préservant ses propriétés intrinsèques, améliorant ainsi la sécurité et le confort de voyage.

2.2. Composants secondaires : anches, capuchons et étiquettes

Diffuseurs à tiges : Optimisation de la diffusion du parfum

- Roseaux en fibres (polymère synthétique) : Ces diffuseurs ont été spécialement conçus pour une diffusion de parfum rapide, constante et optimale. Ils ne se bouchent pas et sont compatibles avec tous types d'huiles parfumées. Bien qu'ils diffusent le parfum plus longtemps, ils sont peu écologiques.

- Roseaux de rotin naturel : Le rotin, matériau naturel, possède des capillaires qui permettent une absorption efficace et homogène de l'huile, assurant ainsi une diffusion plus lente, plus subtile et plus durable du parfum. Biodégradable et renouvelable, il présente toutefois une vitesse de diffusion potentiellement plus lente et peut se décolorer.

- Roseaux de bambou : Source naturelle et renouvelable, mais peu efficace pour la diffusion en raison de ses nœuds internes. Généralement économique, elle nécessite un remplacement plus fréquent.

- Diffuseurs en céramique poreuse (et tiges) : Offrant une diffusion de parfum silencieuse, douce et sans flamme, ces diffuseurs préservent la fragrance pendant des jours, voire des semaines, évitant ainsi son évaporation. En plus d'être une solution écologique, ils constituent de véritables objets de décoration, parfaits pour les petites pièces.

Casquettes : L'alliance de la fonctionnalité et du développement durable

- Bouchons en bois durable : Fabriqués en bois naturel issu de forêts gérées durablement (hêtre, chêne, etc.), ces récipients sont durables, biodégradables et d'aspect naturel. Ils se déclinent en modèles minimalistes, dômes texturés, versions bicolores et bouchons intégrés pour une fermeture sans plastique et un remplissage facile.

- Bouchons métalliques recyclés et recyclables : L'aluminium et le Zamac ont été choisis pour leur recyclabilité, leur longévité, leur agréable toucher et leur polyvalence esthétique. De plus, ils peuvent être plaqués, gravés ou revêtus, assurant ainsi une excellente protection et une étanchéité parfaite.

- Bouchons en bioplastique et en plastique PCR : Les bioplastiques issus de ressources hautement renouvelables (amidon de maïs, canne à sucre, etc.) sont des matériaux compostables, biodégradables et neutres en carbone. Les plastiques recyclés post-consommation (PCR) représentent l'avenir du secteur, comme en témoigne l'utilisation de résine PCR par des marques telles que Glossier pour ses bouchons magnétiques.

- Mécanismes de fermeture magnétique : Une avancée technologique majeure : des aimants intégrés assurent une fixation solide, évitant ainsi les chutes, limitant l’exposition du produit à l’air et préservant l’intégrité du parfum. De plus, l’utilisation est simplifiée grâce à une manipulation aisée d’une seule main et un « clic » très agréable.

- Bouchons diffuseurs passifs : Ces bouchons sont fabriqués à partir d'aluminium, de plastique PP et de mousse PE, et ils sont dotés d'un coussinet en mousse conçu pour une diffusion douce et personnelle d'aromathérapie, sans eau, chaleur ni électricité.

Étiquettes : Information, Esthétique et Intelligence

- Supports d'étiquettes durables : Différents matériaux écologiques tels que le papier recyclé, les adhésifs biodégradables, le vinyle, le PET et le métal sont utilisés, tandis que des papiers spéciaux sont disponibles pour offrir diverses options esthétiques.

- Techniques d'impression avancées :Le gaufrage et le débossage permettent de créer une zone tactile et visuellement contrastée sans encre. Le marquage à chaud offre une excellente finition métallique. Le vernis sélectif UV permet de mettre en valeur certaines parties, tandis que la découpe à l'emporte-pièce permet de créer de nouvelles formes. La tampographie est la technique idéale pour imprimer sur des surfaces courbes avec des détails fins et des encres métalliques. Enfin, l'impression par transfert thermique permet de réaliser des étiquettes très résistantes, en couleur, laminées et découpées sur mesure.

- Technologies d'étiquetage intelligent : Parmi les nombreuses fonctionnalités permises par les puces intégrées dans les « cartouches de parfum intelligentes », on trouve l'authentification dans le cloud, l'enregistrement automatique, la lutte contre la contrefaçon, les algorithmes de diffusion de parfum et la gestion du cycle de vie des cartouches, qui contribuent à améliorer à la fois l'expérience du consommateur et la durabilité.

2.3. Emballage secondaire : Protection et expérience de déballage

L'emballage secondaire ne se limite pas aux étuis pliants ; il comprend également différents emballages ronds et joue un rôle essentiel dans la protection des flacons en verre fragiles pendant le transport. Outre la préservation du parfum, les matériaux opaques bloquent les rayons UV nocifs responsables de sa dégradation, tandis que les boîtes protègent de l'humidité et des chocs.

Le déballage est une étape cruciale du développement de la marque et révèle ses caractéristiques grâce au graphisme, aux couleurs et à la typographie. Pour capter l'attention et enrichir l'expérience visuelle et tactile du client, les emballages de luxe peuvent recourir au gaufrage, au marquage à chaud et à l'impression UV. Les fermetures magnétiques sur les emballages primaires offrent une expérience de déballage unique, contribuant ainsi à la mémorisation de la marque et à la satisfaction client.

L'emballage secondaire écologique, fabriqué à partir de papier/carton recyclé, de carton ondulé, de bambou et de plastiques biodégradables, est de plus en plus plébiscité par l'industrie. Les boîtes pliantes, en particulier, sont mises en avant comme solution recyclable issue de différentes pâtes à papier recyclées, et donc parfaitement adaptées aux consommateurs soucieux de l'environnement.

3. Évaluation des capacités de fabrication pour l'excellence en matière d'emballage de parfums

Choisir un partenaire de fabrication est une décision cruciale qui influe sur plusieurs facteurs tels que la qualité des produits, les économies de coûts, la flexibilité, les délais de livraison et la croissance de l'entreprise. Il est indispensable d'identifier un fournisseur au moyen d'une méthode de qualification complète et fondée sur les risques : cette méthode comprend les étapes suivantes : identification, sélection, évaluation, acceptation, suivi continu des performances et éventuelle disqualification.

3.1. Indicateurs clés de performance (KPI) pour l'évaluation des fabricants

- Contrôle de qualité:

- Taux d'unités défectueuses :La mesure fondamentale de l'intégrité du produit.

- Taux de rebut des matériaux :La norme du secteur est de 3 à 5 % du coût total des matériaux ; si vous la réduisez à moins de 2 %, vous pouvez réaliser un profit important.

- Réclamations des clients : La communication la plus directe concernant la qualité du produit.

- Contrôles spécifiques :Pour l'industrie du parfum, il s'agira de la propreté du flacon, de l'absence de rayures ou de taches, de bouchons bien fermés et fonctionnels, et de l'absence de fuites.

- Rentabilité :

- Coût unitaire et coûts des matières premières : Les questions financières fondamentales liées à la tarification.

- Taux de réduction des déchets : Voici les principaux facteurs qui rendent possibles les économies de coûts.

- Écart de rendement du matériau :L'écart entre l'utilisation réelle et l'utilisation standard des matériaux.

- Retour sur investissement des initiatives durables : Cet indicateur représente le rendement financier des investissements écologiques.

- Avertissement: La recherche exclusive du prix le plus bas peut inévitablement entraîner une baisse de la qualité du produit, une augmentation des dommages pendant le transport et une image de marque ternie.

- Flexibilité de la production :

- Débits et temps de cycle : Mesure de l'efficacité de la commande à la livraison.

- Tarifs de livraison à temps (OTD) : Un niveau supérieur à 95 % est considéré comme bon.

- Capacités de conversion :La capacité de répondre rapidement à une large gamme de styles d'emballage, de tailles et d'options personnalisées.

- Cihaz Kısıtlaması Yok:Présentation d'une augmentation de capacité ainsi que d'équipements multi-applications pour répondre aux volumes annuels estimés.

- Approvisionnement éthique et conformité environnementale :

- Utilisation durable des matériaux : Les indicateurs clés de performance (KPI) possibles sont le pourcentage de matériaux certifiés FSC, PCR, PWR et PIR.

- Gestion de fin de vie : Couvrant la biodégradabilité, la recyclabilité et la compostabilité.

- Consommation d'énergie et émissions de GES : Enregistrement des émissions de portée 1, 2 et 3.

- Taux de valorisation des déchets : Le pourcentage de déchets de fabrication qui ont été détournés des décharges.

- Empreinte carbone des fournisseurs : Évaluer l'impact environnemental de la chaîne d'approvisionnement.

- Pratiques éthiques : L’engagement des fournisseurs envers un code de conduite, des audits par des tiers et des systèmes de traçabilité pour des conditions de travail équitables, la diversité et la sécurité des travailleurs.

3.2. Certifications et audits : garantir la conformité et la qualité

- Certifications :Les normes ISO 9001 (Management de la qualité), ISO 14001 (Management environnemental), ISO 45001 (Santé et sécurité au travail) et SA8000 (Responsabilité sociale) constituent des indicateurs clés de l'engagement d'un fabricant envers la qualité, le respect de l'environnement et le bien-être de ses employés. Pour les emballages pharmaceutiques, la norme ISO 15378 (combinant les normes ISO 9001 et les BPF) est prépondérante.

- Audits d'usine : Les audits sont des instruments indispensables à la réalisation du devoir de diligence, car ils permettent de vérifier la légitimité de l'entreprise, son potentiel de production, la traçabilité des matériaux, les systèmes d'assurance qualité (par exemple, la précision de la découpe, le contrôle du système de collage), les normes de sécurité, les possibilités en matière de recherche et développement, le service après-vente, la transparence de la chaîne d'approvisionnement, l'engagement environnemental et la protection de la propriété intellectuelle. Les audits doivent être menés régulièrement et inclure l'examen des programmes de contrôle qualité internes ainsi que la qualification des fournisseurs de matières premières.

3.3. Atténuation des risques : pièges et protection de la propriété intellectuelle

Les principaux écueils résident dans le choix inapproprié de fournisseurs éloignés (entraînant des coûts plus élevés), le choix basé uniquement sur le prix (ce qui nuit à la qualité), le manque de vision à long terme (absence de considération pour l'expansion future), le report du choix des matériaux, l'absence de spécifications détaillées et un entretien insuffisant des machines. Pour limiter les risques, les entreprises doivent mener une analyse approfondie, instaurer une communication transparente et prendre des décisions éclairées, en ne se basant pas uniquement sur le coût.

La protection de la propriété intellectuelle (PI) est un enjeu majeur, notamment au sein d'une chaîne d'approvisionnement complexe. Si le profil olfactif d'un parfum est difficile à breveter, le design des emballages, la forme des flacons, les logos et l'image de marque peuvent être protégés par des marques déposées, des dessins et modèles industriels et le droit d'auteur. Des contrats solides comportant des clauses d'indemnisation, une meilleure visibilité de la chaîne d'approvisionnement, des procédures de vérification de la disponibilité des brevets et des audits des fournisseurs constituent les solutions. Par ailleurs, la restriction de l'accès aux secrets commerciaux aux seules personnes qui en ont besoin et la mise en œuvre de mesures de sécurité informatique contribuent également à la protection de la PI.

Il est primordial de mettre en place un mécanisme de contrôle de la performance continu et fondé sur les données, qui enregistre les indicateurs clés de performance (KPI) non atteints, analyse les causes profondes des écarts, vérifie la validité des certificats et évalue l'impact financier. C'est ainsi qu'une organisation peut s'améliorer en permanence et prendre des décisions stratégiques.

4. Optimisation de l'approvisionnement mondial et de la dynamique de la chaîne logistique

Le marché mondial des emballages de parfums présente des atouts régionaux distincts qui lui confèrent son caractère unique. Ainsi, l'Europe excelle dans le luxe et l'innovation, l'Asie se distingue par ses coûts compétitifs et sa capacité de production rapide à grande échelle, tandis que l'Amérique du Nord s'efforce de concilier innovation et demande croissante de solutions durables.

4.1. Capacités de production régionales et dynamique du marché

- Europe: En 2024, la part de marché et le chiffre d'affaires s'élevaient à 31,62 %. La France, l'Italie et l'Allemagne abritent les maisons de parfumerie et les fabricants qui en sont les principaux moteurs. Grâce à une réglementation stricte, le secteur est à la pointe de l'innovation respectueuse de l'environnement. Il est réputé pour ses flacons en verre de haute qualité au design exclusif (par exemple, Vetroélite, Verescence) et pour l'utilisation de techniques de décoration modernes.

- Amérique du Nord: Taille et potentiel du marché : Le deuxième marché le plus important devrait atteindre 1,31 milliard de dollars américains d’ici 2032, grâce à la vigueur des secteurs des cosmétiques et des parfums et à l’intérêt croissant pour les emballages durables. Des pôles d’innovation sont situés en Californie et à New York.

- Asie-Pacifique : Les principaux facteurs d'expansion rapide du marché sont la croissance de la classe moyenne et la consommation croissante de produits de luxe en Chine, en Inde, au Japon et en Corée du Sud. De plus, ce secteur est très rentable et permet de produire de grands volumes (par exemple, Daxin Glass et Weiwo en Chine produisent des millions de bouteilles par jour).

4.2. Analyse du coût total à l'arrivée (CTA)

Le coût total de la chaîne d'approvisionnement (CTA) englobe tous les coûts depuis la fabrication du produit jusqu'à sa livraison, tels que le prix du produit, le transport (fret, frais de conteneur, frais portuaires), les droits de douane et les taxes, les frais de courtage, l'assurance, le stockage et la conversion de devises. Une analyse du CTA est essentielle pour identifier les coûts cachés, souvent négligés lorsqu'on se concentre uniquement sur les coûts des matières premières et de la main-d'œuvre. Par exemple, des coûts de main-d'œuvre plus faibles en Asie peuvent être compensés par des coûts de transport et de stockage plus élevés, dus à des délais de livraison plus longs (par exemple, 4 à 6 semaines pour le transport maritime d'Asie vers les États-Unis, soit environ 4 600 $ pour un conteneur de 40 pieds, contre 50 000 $ pour le transport aérien).

4.3. Logistique et délais de livraison

- Réseaux logistiques mondiaux : L'existence d'usines d'emballage appartenant à de grandes entreprises sur différents continents témoigne de l'étendue de leurs réseaux mondiaux.

- Délais de livraison : Les expéditions maritimes d'Asie vers l'Europe/les États-Unis prennent normalement 25 à 35 jours, tandis que le fret aérien pour les commandes urgentes prend 7 à 10 jours.

- Variation du délai de livraison : Pour les modèles simples de bouteilles personnalisées, le délai peut être de 3 à 4 semaines, tandis que pour les finitions spéciales ou les nouveaux moules, il peut être de 5 à 6 semaines.

- MOQ : Les commandes d'essai ont généralement une quantité minimale de commande (QMC) de 500 à 1 000 pièces, tandis que les marques établies commandent de 5 000 à 10 000 pièces par lot. Les quantités minimales de commande pour les flacons en verre et les atomiseurs varient généralement entre 1 000 et 10 000 unités, les modèles en stock ayant des QMC inférieures.

4.4. Stratégies de résilience et d'optimisation de la chaîne d'approvisionnement

- Analyse avancée et IA : L'intelligence artificielle et les algorithmes d'apprentissage automatique jouent un rôle essentiel dans la prévision précise de la demande, l'optimisation des niveaux de stock et la personnalisation de l'expérience client. L'analyse prédictive, alimentée par l'historique des ventes, les tendances saisonnières et les campagnes publicitaires, permet d'éviter le surstockage et les ruptures de stock. De plus, l'analyse des stocks en temps réel favorise la disponibilité des produits les plus demandés et contribue à l'optimisation des performances des fournisseurs et des délais de livraison.

- Gestion des stocks juste-à-temps (JAT) : L'objectif principal est de maintenir les stocks au minimum en n'achetant les matières premières nécessaires qu'au moment opportun. Ainsi, les coûts de stockage et le gaspillage sont réduits, et la rotation des stocks est optimisée. Bien que le juste-à-temps (JAT) présente de nombreux avantages, il est sensible aux interruptions de la chaîne d'approvisionnement et aux fluctuations imprévues de la demande ; il requiert donc des prévisions précises et des fournisseurs de secours fiables.

- Gestion des stocks par le fournisseur (VMI) :Le fournisseur est responsable des stocks de l'acheteur ; il détermine ainsi les niveaux de stock optimaux et les réapprovisionne automatiquement. La gestion des stocks par le fournisseur (VMI) garantit un stock minimal sur site, une réactivité accrue, des délais de livraison courts et une meilleure trésorerie pour les acheteurs, tout en améliorant la précision des prévisions des fournisseurs.

- Transport multimodal et consolidation de fret : La combinaison des transports maritime, aérien, ferroviaire et routier offre le meilleur rapport efficacité/prix/rapidité. Le transport maritime est adapté aux gros volumes de marchandises pour lesquels le coût est le facteur déterminant, tandis que le transport aérien est privilégié en cas d'urgence. Le groupage consiste à regrouper plusieurs petits envois afin d'optimiser l'espace disponible dans les conteneurs.

- Visibilité de la chaîne d'approvisionnement grâce à l'IoT et à la blockchain : Les objets connectés (capteurs, étiquettes RFID/NFC, etc.) permettent de suivre en temps réel la localisation et l'état des produits, améliorant ainsi la traçabilité et luttant efficacement contre la contrefaçon. La technologie blockchain garantit un enregistrement sécurisé et transparent, ainsi que la traçabilité de toute modification. Elle offre aux consommateurs de produits de grande valeur, comme les parfums, une visibilité complète et une exactitude des données optimale.

- Dédouanement et réglementation : Les parfums, en raison de leur teneur en alcool, sont classés comme matières dangereuses (Hazmat) et nécessitent donc un étiquetage spécifique, un emballage conforme aux normes ONU et un transport interdit. Outre ces aspects, une documentation détaillée, telle que les factures commerciales, les certificats d'origine et les déclarations de matières dangereuses, est essentielle. Le respect du règlement REACH de l'UE et l'utilisation des codes SH appropriés sont deux autres facteurs déterminants.

- Impact des méthodes d'expédition : À titre de comparaison, le transport maritime est de 5 à 12 fois plus rentable et de 15 à 47 fois plus respectueux de l'environnement que le transport aérien, qui, bien que beaucoup plus rapide, est nettement plus cher et génère une empreinte carbone plus importante. Le transport ferroviaire, quant à lui, allie prix abordable, fiabilité et respect de l'environnement.

- Optimisation stratégique des emballages : Pour un système d'emballage plus efficace, il convient d'éliminer les espaces superflus, d'utiliser des emballages réutilisables associés à un système de logistique inverse performant, et d'utiliser un étiquetage précis (par exemple, des codes QR) qui facilite le suivi et contribue à l'efficacité. Les bouteilles en verre fragiles doivent être emballées avec des matériaux de protection adaptés, voire conditionnées individuellement.

- Diversification et localisation : Pour renforcer leur stabilité face aux changements géopolitiques, aux réglementations commerciales et aux perturbations qui en découlent, les entreprises ont adopté la stratégie de relocalisation de leurs fournisseurs (relocalisation/relocalisation de proximité) ainsi que de diversification de leurs réseaux. Cette démarche réduit leur dépendance à l'égard d'une source d'approvisionnement unique et, simultanément, atténue les risques liés aux crises mondiales et aux restrictions commerciales.

- Contrôle de la température et manutention spécialisée : Les parfums doivent être transportés dans des véhicules propres, inodores et, dans la plupart des cas, à température contrôlée, et stockés dans des entrepôts similaires afin de préserver leur qualité. Une manipulation particulière des produits permet de les protéger de toute détérioration due à des conditions environnementales inappropriées et de tout dommage.

4.5. Évolutions géopolitiques et politiques commerciales

Les droits de douane ont pour effet d'accroître directement les coûts de production et de perturber les chaînes d'approvisionnement mondiales. De ce fait, les économies de la région Asie-Pacifique sont les plus vulnérables aux pressions inflationnistes.

5. Conclusion

Le secteur de l'emballage des parfums est un secteur en constante évolution, qui exige une innovation continue en matière de conception, de matériaux et de gestion de la chaîne d'approvisionnement. MostebIl sera essentiel d'utiliser des traitements de pointe pour le verre, des matériaux écologiques comme la pâte à papier moulée et le mycélium, ainsi que des technologies d'emballage intelligentes afin de différencier la marque sur le marché. Le choix judicieux de partenaires, étayé par des indicateurs clés de performance (KPI) rigoureux et des audits approfondis, est la clé pour garantir la qualité et la conformité. Enfin, Mosteb pourra faire face aux complexités géopolitiques et répondre à l'évolution des attentes des consommateurs en matière de luxe, de durabilité et d'expériences personnalisées grâce à l'optimisation de son approvisionnement mondial via l'analyse de données pilotée par l'IA, une logistique diversifiée et des stratégies de chaîne d'approvisionnement résilientes.