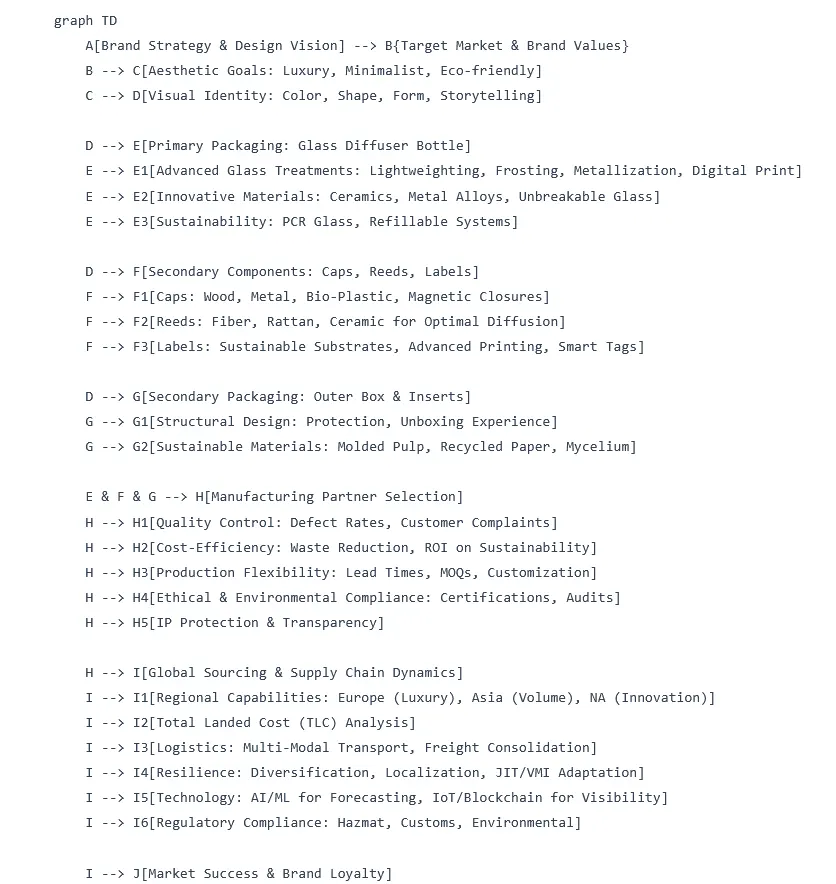

A leading glass diffuser bottles factory report reveals that the global fragrance packaging market, valued at approximately USD 3.52 billion in 2024 and projected to reach USD 5.83 billion by 2035, is undergoing a profound transformation driven by evolving consumer preferences, technological advancements, and a growing demand for sustainability. For brands like Mosteb, navigating this complex landscape requires a strategic approach to design, material innovation, manufacturing partnerships, and supply chain optimization. This report delves into these critical areas, providing a comprehensive overview of the current state and future directions, with a particular focus on the capabilities of a leading glass diffuser bottles factory to meet the exacting standards of luxury fragrance.

1. Crafting Your Brand's Visual Identity

Visual identity via fragrance packaging is so much more than just a container; it is a “tactile prologue” that, communicates brand values, emotionally connects with, and establishes a consumer’s cherished ritual. Every design decision, down to the very last detail, has to reflect the brand’s tone of voice i.e., whether it is a luxury brand, a minimalist one, an eco-friendly one, or a brand targeting the mass market.

1.1. The Art of Storytelling Through Design

Packaging of luxury perfumes becomes a brand storytelling tool of an extraordinary power by turning the mere act of purchase into an immersive experience. The feeling of the product, the chosen color, and the weight all work together in perfect harmony to extend the brand’s emotional connection with the customer and to lift the perfume above its ordinary functional role, thus making the brand more recognizable and loyal to the customer.Attention to minute details such as the exactness of the logo embossing, the subtlety of the paper texture, the smoothness of the satin ribbon, or the brilliance of the metallic foil is of the utmost importance. All these factors commit the brand to artisanship and exclusivity and quality control done in the most stringent way ensures that the highest excellence standards are met.

1.2. The Sensory Experience: Touch, Sight, and Sound

Luxury packaging heavily depends on the “touch” element which includes tactile attributes like soft-touch paper, silk or velvet linings, cool and heavy glass, and well-designed magnetic caps that together provide a multisensory unboxing experience. Soft-touch coatings offer a velvety touch, thus pleasing the senses and giving out a luxurious impression. Besides this, embossing (raised patterns), debossing (indented patterns), and foil stamping (metallic accents) not only create physical depth and glamour, but also make the brand more memorable and give the consumer a nice tactile experience. The appearance and feeling to the touch are enhanced even more by special finishings like spot UV on logos, holographic film, or varnishing/frosting on the glass of the bottles. Even the “click of quality” from a well-crafted spray nozzle and a magnetic closure cap, thus, it is the small things made with precision that make up the luxury packaging.

In the end, packaging is the main factor that first-hand impacts the value and quality as to be seen, it is the reason for premium price points. Luxury packaging is perceived by consumers as a hallmark of exclusivity and prestige, with a research survey that 72% of shoppers are influenced by the packaging design while 61% are more likely to repeat a purchase if it is in luxury packaging. The emotional bond created during the storytelling and the ritualized unboxing is what ultimately loyalty and repeated purchases generate.

2. Comprehensive Packaging Design & Material Innovation: The Glass Diffuser Bottles Factory Approach

Brand experience through packaging is the integration of the entire packaging components spanning from primary glass diffuser bottle to caps, reeds, labels, and secondary packaging. Here, besides the uniformity of the brand experience, the article also talks about surface treatments on glass, eco-friendly materials, and innovative production techniques that set the standard for the next-generation fragrance packaging.

2.1. Primary Packaging: The Heart of the Fragrance

The Glass Diffuser Bottles Factory processes emphasize that glass remains the best option for luxury fragrance bottles due to its beauty, durability, excellent preservation of the scent, and the ability to convey high quality. The weight and the thickness of the glass bottle are basically the things that really make the product look more expensive.

Advanced Glass Treatments and Innovations

- Lightweighting:Borosilicate glass allows for thinner walls of the bottle, thus the total weight and the carbon emissions related to transportation are reduced. The DobleAlto technique by Estal creates an optical illusion of a taller and heavier bottle without increasing the glass volume or weight and thus a luxury feel is maintained while the sustainability factor gets better.

- Enhanced Barrier Properties: Internal colored coatings, such as those from Heinz-Glas, can both emphasize the attractive features of glass and provide barrier properties. Frosted glass, which can be obtained by different methods, offers very important UV protection thus the light-sensitive fragrance formulations are kept safe.

- Sophisticated Surface Texturization:The acid etching method can produce a smooth, translucent, matte, or even opaque frosted surface which brands like Chanel and Dior use for their complex designs and for the silky “peach-skin” like tactile sensation. Sandblasting gives a more coarse surface, whilst spray frosting is used for decorative purposes, UV protection, and enhanced grip.

- Metallization: The process involves attaching very thin layers of metals (e.g., gold, silver, aluminum) to the glass thus metal can improve wear resistance, conductivity, reflection, and corrosion resistance, at the same time, the glass will have a high-gloss, shiny metal-texture appearance. With the help of this method, it is possible to achieve translucent metallization, metallic gradients, and textured finishes.

- Gradient Effects: Gradient color effects, which account for 18-22% of the premium fragrance market, is a trend that can be realized either by advanced glass-coating techniques or metal powder color blending.

- Versatile Digital Printing: The process of digital printing is the one by which high-quality, vivid, full-color designs, photo-realistic images, and complex patterns are directly printed on glass by means of UV-curable inks. The method is very flexible and quite economical in case of short production runs and quick customization.

- Diverse Decoration Techniques:The other methods are screen printing (versatile, durable), pad printing (curved surfaces, precise details), hot stamping (metallic foil of a luxurious nature), and glass engraving/laser etching (intricate, permanent designs). Additionally, holographic coating is a stable, colorful, plated layer.

Innovative Primary Packaging Materials Beyond Glass

While glass dominates, other materials are emerging for primary packaging, particularly for diffusers:

- High-Performance Ceramics: Ceramic diffusers offer a premium, elegant, and minimalist aesthetic, blending seamlessly with home decor.They provide superior heat resistance, contributing to a longer product lifespan, and their density minimizes operational noise 89. Ceramic surfaces are also easier to clean and maintain.

- Lightweight Metal Alloys: Metals like aluminum and titanium offer a modern, minimalist aesthetic, allowing for intricate detailing and unconventional bottle shapes.CNC aluminum alloy canisters with refillable bottles promote sustainability by reducing plastic waste.

- “Unbreakable Glass” Technology: Verescence has introduced a spray technology that wraps glass like a second skin, making it resistant to breakage while maintaining its intrinsic properties, enhancing safety and travel convenience.

2.2. Secondary Components: Reeds, Caps, and Labels

Diffuser Reeds: Optimizing Scent Diffusion

- Fiber Reeds (Synthetic Polymer): These were specifically designed to provide the fastest, most constant, and most efficient scent release. They do not clog and can be used with any type of fragrance oil. Although they give off fragrance for a longer time, they are not very environmentally friendly.

- Natural Rattan Reeds: Rattan, being a natural material, has capillaries that provide efficient and even absorption of the oil, thereby allowing a slower, more subtle, and longer-lasting release of the fragrance. They are both biodegradable and renewable, however, their diffusion rate may be slower and they may change color.

- Bamboo Reeds: A natural and renewable source but not very efficient for diffusion because of the internal nodes. Commonly, it is a budget-friendly option that needs to be replaced more frequently.

- Porous Ceramic Diffusers (and Reeds): Offer a very quiet, gentle, and flameless way to continuously emit a scent, thus, preventing the fragrance from evaporating and saving it for days or even weeks. Besides being a great eco-friendly solution, they also serve as decorative pieces, perfect for smaller rooms.

Caps: Functionality Meets Sustainability

- Sustainable Wood Caps: Made of natural wood sourced sustainably (e.g., beech, oak), they provide long-lasting use, are biodegradable, and have a natural look. The innovations are such that there are minimalist models, textured domes, two-tone versions, and built-in stoppers for plastic-free sealing and refillability.

- Recycled and Recyclable Metal Caps: Aluminum and Zamac are chosen for their recyclability, longevity, good tactile, and aesthetic versatility. Besides that, they can be plated, etched, or coated, thus providing not only a very good protection but also a tight seal.

- Bio-Plastic and PCR Plastic Caps: Bio-plastics made of highly renewable sources (e.g., corn starch, sugarcane) are materials of compostable, biodegradable, and carbon-neutral products. Post-Consumer Recycled (PCR) plastics are the future of the industry, as a brand like Glossier is already using PCR resin for magnetic caps.

- Magnetic Closure Mechanisms: A major change in technology with magnets integrated for a firm installation, thus avoiding drops, reducing the exposure of the product to the air, and keeping the fragrance intact. Besides that, they give an enhanced user experience as the operation is easy with one hand, and the “click” sound is very pleasant.

- Passive Diffuser Caps: Aluminum, PP plastic, and PE foam are the materials from which these caps have been made, and they feature a foam pad designed for gentle, personal aromatherapy diffusion without the need for water, heat, or electricity.

Labels: Information, Aesthetics, and Intelligence

- Sustainable Label Substrates: Different eco-friendly materials such as recycled paper, biodegradable adhesives, vinyl, PET, and metal are been used, while specialty papers are available for providing various aesthetic options.

- Advanced Printing Techniques:Both embossing and debossing can be used to create a tactile and visually contrasting area without the use of ink. An excellent metallic finish is given by the foil stamping. With the help of Spot UV, certain parts can be displayed and die-cutting allows for new shapes to be formed. The best option for printing curved surfaces with small details and using metallic inks is pad printing. The most durable, full-color, laminated, and custom-cut labels can be done through thermal transfer printing.

- Smart Label Technologies: One of the many features enabled by integrated chips in “intelligent scent cartridges” is cloud authentication together with auto-registration, anti-counterfeiting, scent diffusion algorithms, and lifecycle cartridge management, which help to improve both consumer experience and sustainability.

2.3. Secondary Packaging: Protection and Unboxing Experience

Secondary packaging is not limited to only folding cartons but also includes different round designs, and they play a vital role in the protection of fragile glass bottles during shipping. Besides protecting the scent from going off, opaque materials also block the harmful UV rays that cause fragrance degradation, while boxes can be used as barriers against the humidity and physical protectors against shocks.

Unboxing is a very important part of the brand extension and it shows the brand’s traits through the use of graphic design, colors, and typography.To attract more attention and to improve the visual and tactile experience of the customer, luxury packaging may use embossing, hot foil stamping, and UV printing.Magnetic closures on primary packaging allow for distinctive unboxing moments, thus, contributing to brand memorability and customers’ satisfaction.

Environmentally friendly secondary packaging, made of recycled paper/board, corrugated cardboard, bamboo, and biodegradable plastics, is being more and more embraced by the industry. Folding cartons, are especially emphasized as a recyclable solution made from different recycled pulps, thus, being suitable for environmentally aware consumers.

3. Evaluating Manufacturing Capabilities for Fragrance Packaging Excellence

Choosing a manufacturing partner is a pivotal move that influences several factors such as product quality, cost savings, flexibility, lead times, and business growth. Identifying a supplier through a comprehensive and risk-based qualifier is a must: the steps comprise identification, selection, evaluation, acceptance, continuous performance monitoring, and possible disqualification.

3.1. Key Performance Indicators (KPIs) for Manufacturer Evaluation

- Quality Control:

- Defective Units Rate:The fundamental measure of product integrity.

- Material Scrap Rate:The industry standard is 3-5% of total material costs; if you cut it to less than 2% you can make a large profit.

- Customer Complaints: The most straightforward communication of quality of the product.

- Specific Checks:For the fragrance industry these will be the cleanliness of the bottle, the absence of scratches or stains, tightly secured and working caps, and no leakage.

- Cost-Efficiency:

- Unit Cost & Raw Material Costs: The basic money matters of pricing.

- Waste Reduction Rates: These are the main factors that make cost savings possible.

- Material Yield Variance:The discrepancy between real and standard material usage.

- ROI for Sustainable Initiatives: This indicator is a financial return from eco-friendly investments.

- Warning: Only chasing the lowest price may inevitably result in poorer product quality, increased damages during transportation, and a tarnished brand image.

- Production Flexibility:

- Throughput Rates & Cycle Time: The efficiency measurement from order to delivery.

- On-Time Delivery (OTD) Rates: The level of 95%+ is considered good.

- Changeover Capabilities:The ability to respond quickly to a wide range of pack styles, size, and personalized options.

- Scalability:Exhibition of a capacity increase along with multi-application equipment to fulfill estimated annual volumes.

- Ethical Sourcing and Environmental Compliance:

- Sustainable Material Usage: Possible KPIs are the percentage of FSC-certified, PCR, PWR, and PIR materials.

- End-of-Life Management: Covering biodegradability, recyclability, and compostability.

- Energy Consumption & GHG Emissions: Recording of Scope 1, 2, and 3 emissions.

- Waste Diversion Rates: The percentage of manufacturing waste that has been diverted from landfills.

- Supplier Carbon Footprint: Evaluating the impact on the environment caused by the supply chain.

- Ethical Practices: Suppliers’ commitment to a code of conduct, third-party audits, and traceability systems for fair labor, diversity, and worker safety.

3.2. Certifications and Audits: Ensuring Compliance and Quality

- Certifications:ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 45001 (Health & Safety), and SA8000 (Social Accountability) can be considered as the primary signals which show that a manufacturer is committed to quality, being environmentally friendly and taking care of the workers. For pharmaceutical packaging, ISO 15378 (which is a combination of ISO 9001 and GMP) is the most important one.

- Factory Audits: Audits are necessary instruments for the performance of due diligence as they check the legitimacy of the business, the production potential, the traceability of the materials, the quality assurance systems (for example, the precision of the die-cutting, the control of the gluing system), the safety standards, the R&D possibilities, the after-sales service, the openness of the supply chain, the giving back to nature, and the protection of the intellectual property.Audits must be conducted frequently and include examinations of the internal QC programs and the qualification of the raw material suppliers.

3.3. Mitigating Risks: Pitfalls and IP Protection

The main stumbling blocks are the wrong choices of suppliers who are far away (which leads to higher costs), choosing only by price (which causes poor quality), forgetting next step by not considering future expansion, postponing material selection, not providing detailed specifications, and bad maintenance of the machines. To lessen the risk, companies have to carry out a full due diligence, engage in clear communication, and decide wisely without considering the cost only.

Intellectual property (IP) protection is one of the most important issues, particularly in a complicated supply chain. However, while a fragrance scent profile is hard to patent, the packaging designs, the shape of the bottle, the logos, and the branding can be protected by trademarks, industrial designs, and copyright. Strong contracts with clauses for indemnity, better supply chain visibility, patent clearance procedures, and vendor audits are the answers. Besides this, restricting access to trade secrets on “need-to-know” basis and using IT security measures also help IP protection.

It is of utmost importance to have a constant, data-driven performance control mechanism in place, which records the KPIs that have not been achieved, performs the root cause analysis for the discrepancies, checks the validity of the certificates, and evaluates the monetary aspect. This is the way for an organization to continuously improve and take strategic decisions.

4. Optimizing Global Sourcing and Supply Chain Dynamics

The global fragrance packaging market has different regional benefits that make it unique. Thus, Europe is very good at providing luxury and innovation, Asia is a very cheap and can produce a large quantity very quickly, while North America tries to combine the innovation with the increasing demand for sustainable solutions.

4.1. Regional Manufacturing Capabilities and Market Dynamics

- Europe: Market share and revenue-31.62% in 2024, France, Italy, and Germany are home to”],[“perfume houses and manufacturers that are the main drivers. It is the leader in environmentally friendly innovation due to strict regulation. It is famous for the specially designed high-quality glass bottles (for instance, Vetroelite, Verescence) and the use of the modern decoration techniques.

- North America: Market size and potential- The second-largest market is expected to reach USD 1.31 billion by 2032, supported by the two robust industries of cosmetics and fragrances and the focus on the sustainable type of packaging. Innovation hubs in California and New York.

- Asia-Pacific: Most rapid market expansion factors- a growing middle class and an increasing luxury goods consumption in China, India, Japan, and South Korea. In addition, it is very cost-effective and can produce high volumes (for instance, Daxin Glass, Weiwo in China producing millions of bottles daily).

4.2. Total Landed Cost (TLC) Analysis

TLC includes all costs from the time the product is manufactured until it is delivered, such as product price, transportation (freight, container fees, port charges), customs duties and taxes, brokerage fees, insurance, inventory holding, and currency conversion.A TLC analysis is extremely important in finding out the hidden costs that are usually disregarded when giving material and labor costs the sole focus. For instance, lower labor costs in Asia may be neutralized by higher freight costs and inventory carrying costs due to longer lead times (e.g., 4-6 weeks for sea freight from Asia to the US, costing around $4,600 for a 40-foot container, versus $50,000 for air freight).

4.3. Logistics and Lead Times

- Global Logistics Networks: The existence of packaging factories of major companies on different continents is evidence of their global networks, which are well developed.

- Shipping Times: Sea shipments from Asia to Europe/USA normally take 25-35 days, while air freight for urgent orders is 7-10 days.

- Lead Time Variation: For straightforward designs of customized bottles, it may be 3-4 weeks, while for special finishes or new molds, the time may be 5-6 weeks.

- MOQs: Trial orders typically have MOQs of 500-1,000 pieces, while established brands purchase 5,000-10,000 pieces per run. Minimum order quantities for glass bottles and atomizers usually range between 1,000 and 10,000 units, with the stock designs having lower MOQs.

4.4. Supply Chain Resilience and Optimization Strategies

- Advanced Analytics and AI: Artificial intelligence and machine learning algorithms play a significant role in demand forecasting that is accurate, stock levels optimization, and customer experiences personalization. Predictive analytics powered by historical sales data, seasonal trends, and advertising activities helps to avoid both overstocking and stockouts. Moreover, the inventory analytics performed in real time promote the availability of the most demanded products and also support the supplier performance and the delivery time optimization.

- Just-in-Time (JIT) Inventory Management: The main goal is to keep the stock at a minimum level through the procurement of the necessary materials only when they are required. In this way, holding costs, wastes are reduced and the warehouse turnover is improved. Although the JIT has many advantages, it is susceptible to supply chain interruptions and unexpected fluctuations in demand; therefore, it needs precise forecasting and dependable backup suppliers.

- Vendor-Managed Inventory (VMI):The supplier is responsible for the buyer’s inventory, thus, deciding on the best stock levels and automatically replenishing them. VMI ensures very little inventory on-site, quick response, rapid lead times, and better cash flow for the buyers while at the same time, it improves the accuracy of the suppliers’ forecasting.

- Multi-Modal Transport and Freight Consolidation: The combination of sea, air, rail, and road transport is the best way to get the advantages of efficiency, low price, and speed. Sea freight is suitable for large volumes of goods where cost is the main factor, while air freight is used when the urgency of delivery is the highest. Freight consolidation is the process whereby small shipments are put together to make full use of the available cargo space.

- Supply Chain Visibility with IoT and Blockchain: IoT devices (e.g. sensors, RFID/NFC tags) offer the possibility of real-time monitoring of not only the location but also the condition of the products, thus, improving the traceability and giving a tough fight to the counterfeit goods. Concerning the record-keeping, Blockchain guarantees that it is done safely, transparently and any changes can be traced, providing not only end-to-end visibility but also data accuracy to the customers of high-value products such as perfumes.

- Customs Clearance and Regulations: Fragrances due to their alcohol content have been categorized as hazardous materials (Hazmat), thus, requiring the provision of special labels, packaging that meets UN standards, and prohibited transport. Alongside other aspects, detailed documentation such as commercial invoices, certificates of origin, and declarations of hazardous goods plays a very important role in the process. Meeting the EU REACH regulation requirements and using the correct HS codes are two other highly important factors.

- Shipping Methods Impact: To give a comparison, sea freight is from 5 to 12 times more cost-efficient and from 15 to 47 times more environmentally friendly than air freight, which, however, is much faster but significantly more expensive and with a higher carbon footprint. On the other hand, rail provides a combination of affordability, dependability, and environmental-friendliness.

- Strategic Packaging Optimization: The steps towards a more efficient packaging system are the elimination of the extra space in the packages, the use of reusable packaging coupled with an efficient reverse logistics system, and the accurate labeling (for example, QR codes) which not only facilitates tracking, but is also a measure of efficiency. Fragile glass bottles have to be packed with adequate protective materials and even individually bagged.

- Diversification and Localization: To increase their stability against geopolitical changes, trade regulations, and the resulting disruptions, businesses have taken the strategy of localizing suppliers (reshoring/nearshoring) as well as diversifying the networks of suppliers. This step reduces dependence on those single sources of supply and at the same time, lessens the dangers coming from global crises and trade restrictions.

- Temperature Control and Specialized Handling: Perfumes need to be transported in clean, odorless, and in most cases temperature-controlled vehicles, and stored in similar warehouses if their quality is to be maintained. Special handling of the products is what keeps them safe from both deteriorating due to inappropriate environmental conditions and getting damaged.

4.5. Geopolitical Shifts and Trade Policies

Tariffs have the effect of directly increasing the cost of production and creating disruptions in global supply chains. In this regard, Asia-Pacific economies are the ones that are most vulnerable to inflationary pressures as a result.

5. Conclusion

The perfume packaging sector is a fast-moving one, requiring continuous innovation in the aspects of design, materials, and the management of the supply chain. For Mosteb, it will be very important to use advanced glass treatments, eco-friendly materials such as molded pulp and mycelium, and smart packaging technologies in order to differentiate the brand in the market. The right choice of partners, supported by strong KPIs and thorough audits, is the way to ensure quality and compliance. In the end, Mosteb will be able to deal with geopolitical complications and satisfy the change of consumer demands for luxury, sustainability, and personalized experiences by global sourcing optimization through AI-driven analytics, diversified logistics, and resilient supply chain strategies.